Shingle

Perfect for: Educational buildings, Commercial buildings, Flat to pitch, Community centres and many other types of buildings and projects

Features & Benefits

- Manufactured in Britain

- Hidden-fix interlocking design

- Suitable for roof pitches down to 15°

- BROOF(t4) fire certification (BS EN 13501-5)

- 50-year weather-seal warranty

Shingle Overview

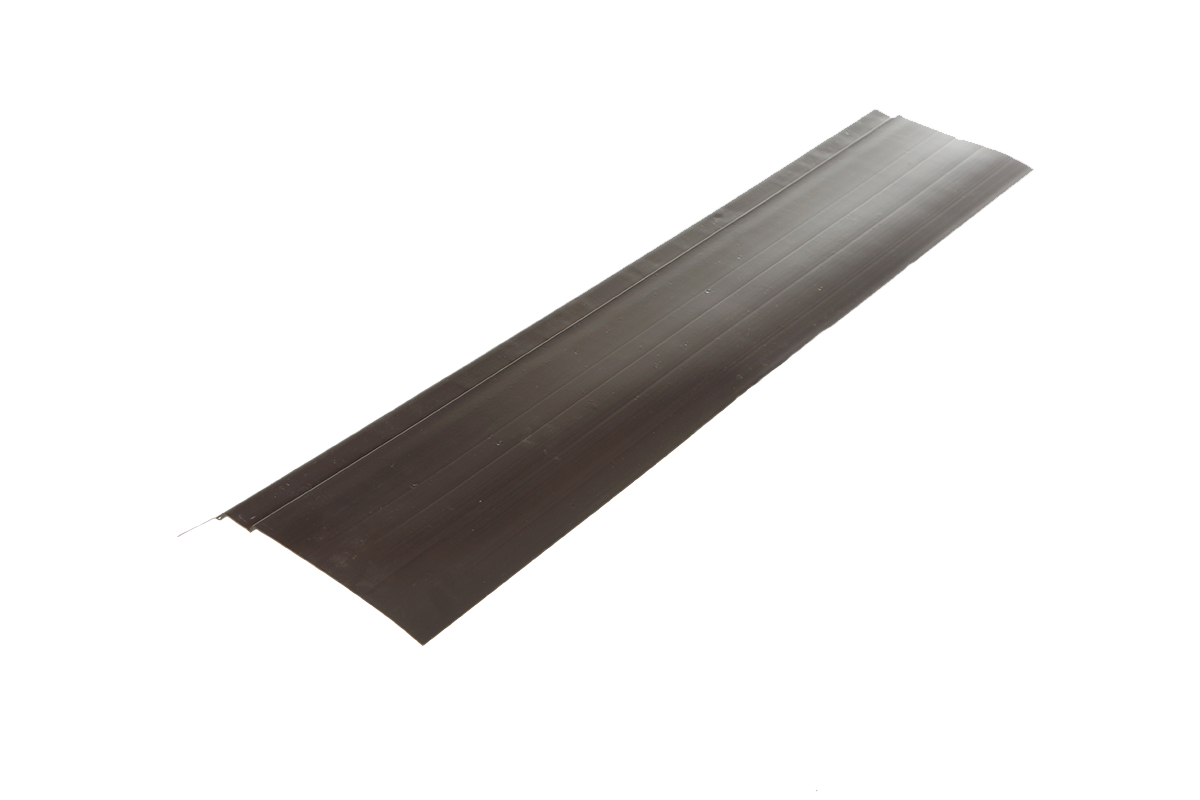

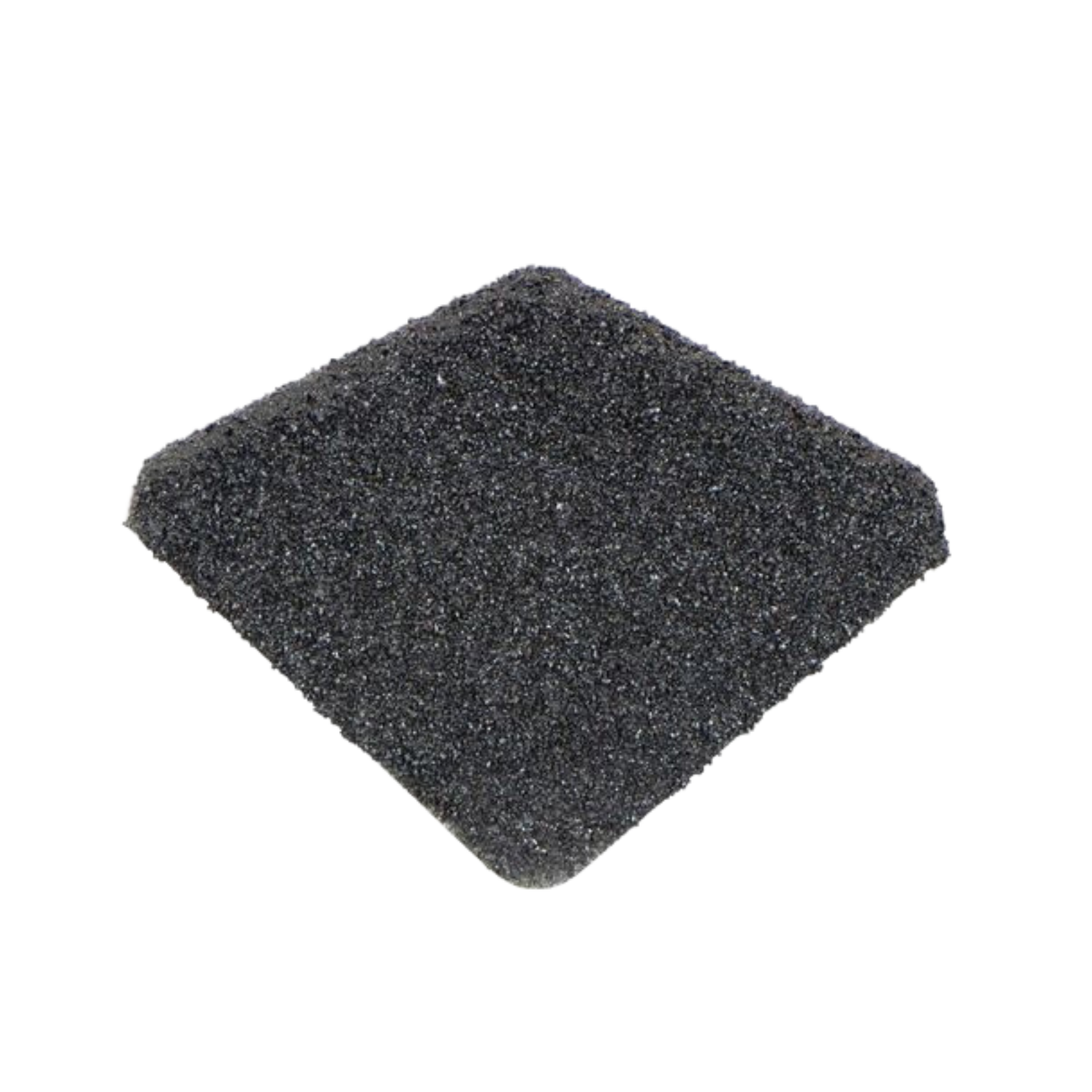

The Britmet Shingle tile is designed to give an authentic shingle effect available in the largest standard colour range in the UK. Shingle is designed for roof pitches from 15° to 90°. Britmet Shingle is 1231mm (width) x 250mm (height). This lightweight roofing panel is designed to emulate natural slates and must be fixed with a broken bond finish, in a right to left fashion. Shingle is manufactured using the highest grade Aluzinc steel, coated with a stone granule finish and a clear, acrylic overglaze.

With all the characteristics you could expect from traditional American shingle, the Britmet Shingle is unique with a fully dry-fix, interlocking hidden-fix design to keep your roof flush from fixings. Unlike traditional shingle, our lightweight tile design offers the perfect solution to any project. Despite having a steel base, the Britmet shingle weighs just under 7kg per sqm!

Most importantly, you can have a sound piece of mind using the Britmet Shingle as we are proud owners of an AA fire classification (BS476-3) (equal to traditional roof tiles and slates) and we are proud to offer a 50-year guarantee against weather penetration.

Raven

Titanium Grey

Bramble Brown

Rustic Brown

Rustic Terracotta

Tartan Green

Rustic Red

Smoked Oak

Shingle Brochure

Shingle Photo Gallery

Shingle Product Range

Shingle Technical Spec

| Min. pitch: | 15° |

| Max. pitch: | 90° |

| Overall width: | 1326mm |

| Cover width: | 1231mm |

| Side lap: | 95mm |

| Step: | 20mm |

| Batten gauge: | 250mm |

| Roof cover per slate: | 0.308m2 |

| Slates per m2: | 3.2 |

| Steel base: | 0.40mm |

| Weight as laid per sqm: | 7kg |

| Fire resistance: | AA classification equal to traditional roof tiles and slates |

Shingle General Specification

Shingle is designed for roof pitches from 15° to 90°.

Britmet Shingle is 1231mm(width) x 250mm(height). This

lightweight roofing slate panel is designed to emulate

natural slates and must be fixed with a broken bond

finish, fixed in a right to left fashion.

Fascia Boards:

Fix timber or UPVC fascia boards with the top edge to be

approximately a batten thickness above rafters (if the

fascia is used as eaves batten).

Battens:

Fix the tiling battens to rafter at 250mm centres (front of batten) up from the eaves which will be 250mm less overhang of the tile into the gutter, usually 40mm.

Please note: It is the responsibility of the installer to

ensure correct batten usage.

Underlay / Breather Membrane:

Approved roofing underlay is to be laid over rafters,

lapped and secured to the rafters with galvanised clout

nails and carried well into the gutters. All to comply with

current regulations.

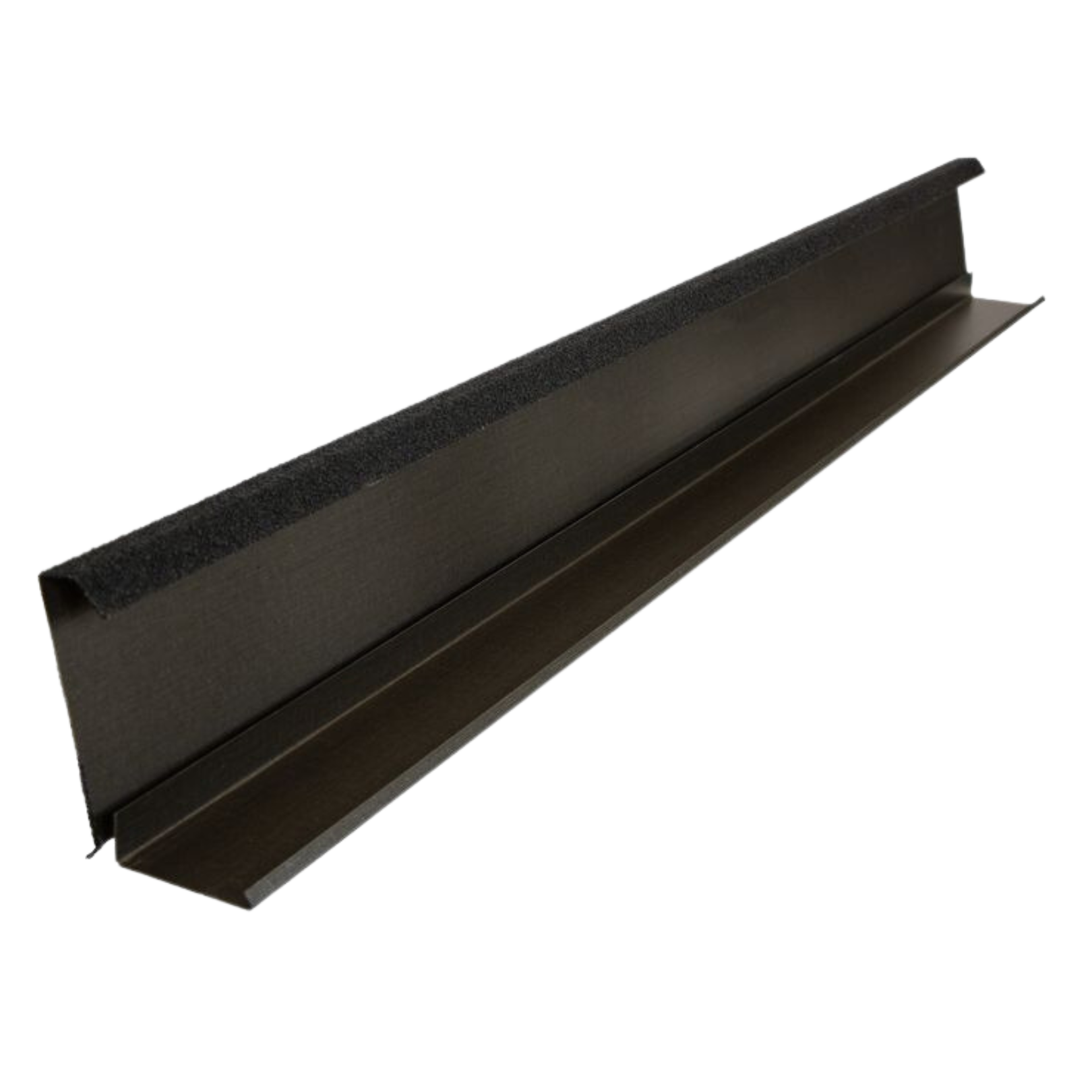

Two-Part Barge Soaker:

Fix the timber or UPVC barge boards with their top

approximately 25mm above the top of tiling battens to

allow for the side of the watercourse to be supported.

Fix the soaker section of the two-part barge soaker on

the top of the battens at the gable ends and against

the inside of the barge boards. Grip the nails over to

hold and fix them into the battens. Then, screw fix on

sides into barge board if necessary. Overlap sections

by around 25mm. Fix the outer section of the twopart

barge soaker by nailing into the top and sides of

the barge board at evenly spaced intervals. Overlap

sections by approximately 25mm. Bend the inner flange

resting on top of tiles as required. Cut and bend to dress

the end of the bottom section as required. One part

covers 5 courses of tiles.

Tiling on Felt and Battens:

Starting at the bottom right-hand side of the roof, fix

the first shingle using 4 nails or screws evenly. Then,

working from right to left, continue laying each shingle

in the same way making sure that the side and end

laps interlock correctly. At the eaves, nail each tile at its

lowest possible point into the eaves batten/fascia. At

this point, you can use the touch-up kit to paint over the

heads of the nails. Always try to use cut-offs from the

previous course to start the next course or use a half

tile to ‘break the bond’. Again, working from right to left,

fix the next subsequent shingle ensuring side/end/nose

laps interlock correctly. Use half tiles or cut-offs to start

the next course. Hook the nose of your upper tile into the

lip of the tile below ensuring a tight fit (the heel of your

hand or a block of wood can be used to gently knock the

tiles together) Continue with each successive course.

Tiling on Board:

For a warm boarded roof is critical that you have a 25mm

air gap between the boarding and the underside of the

tiles/felt. Securely fix through the boarding and into the

rafters below, a 50mmx25mm counter rafter running from

eaves to the ridge at approx. 900mm centres. Fix your

battens to the top of these counter rafters at 250mm

centres, apart from the first batten from the eaves which

will be 250mm less the overhang of the tile into the gutter,

which is usually around 40mm.

Angle ridge flashing:

At the ridge course of the tiles, trim to suit if required using

the apex line of the roof as the cut line. Attach a timber

batten on top of the shingle of the ridge using a ridge cap

as a guide. Secure the ridge caps to battens using four

nails per side. Take ridge cap to the full length of ridge and

notch to overlap onto the two-part barge soaker.

Ridge End Cap:

Fix the Ridge End Cap by sliding into the ridge as shown in the image above.

Note: You may need to notch the sides of the

End Cap to allow it to slide in freely.

Angle hip flashing:

A 38mm x 38mm batten should be nailed to the slate

battens on each side of the hip using galvanised nails.

Shingle panels can be cut and bent up against the

battens, using a guillotine and bender (available to hire

from Britmet). The hip caps should be fitted over the

battens and nailed through the downturn into the face of

the battens, using 5 nails on each side.

Eaves:

The bottom course of shingle panels is to be secured

with 4 coloured galvanised 2.6mm x 50mm nails driven

vertically through the high point of the slate panel profile,

into the fascia board, or through the eaves batten. The

Eaves batten is to be placed approximately 20mm behind

the fascia board if the Britmet eaves ventilation system

is used. The nail heads need to be sealed using Britmet

touch-up kit The top of the fascia board or eaves vent is

used, to be in line with the top of the battens. Fit lay board,

or tilting fillet, at the eaves, if appropriate, to ensure any

moisture on the underlay drains into the gutter.

Valley:

Valley can be formed from a metal sheet (lead) or

moulded glass fibre or similar approved lining, supported

on valley boarding. Adjacent Shingle panels should be

measured and cut, allowing a sufficient downturn, as

detailed in the manufacturer’s instructions. Battens to

project over the valley to provide fixing for slate panels.

Sidewall flashing:

Britmet sidewall flashing must be secured with fixing nails,

one driven vertically into each batten (these nails need

to be covered, using Britmet touch-up kit). Britmet cover

flashing should be dressed over the edge of side flashing

abutting the wall and let into the brickwork.

Shingle Installer Guide

Shingle Videos

Shingle Technical Drawings

| Ref | Description | Files |

| BLR-CAD-SHINGLE-0001 | Shingle | DWG | JPG |

| BLR-CAD-SHINGLE-0002 | Shingle | DWG | JPG |

| BLR-CAD-SHINGLE-0003 | Shingle | DWG | JPG |

| BLR-CAD-SHINGLE-0004 | Shingle | DWG | JPG |

| BLR-CAD-SHINGLE-0005 | Shingle | DWG | PDF |

| BLR-CAD-SHINGLE-0006 | Shingle | DWG | PDF |

| SK-101 | Eaves Detail | |

| SK-102 | Valley Detail | |

| SK-103 | Hip Ridge Detail | |

| SK-104 | Verge Detail | |

| SK-105 | Shingle Tile | |

.png)