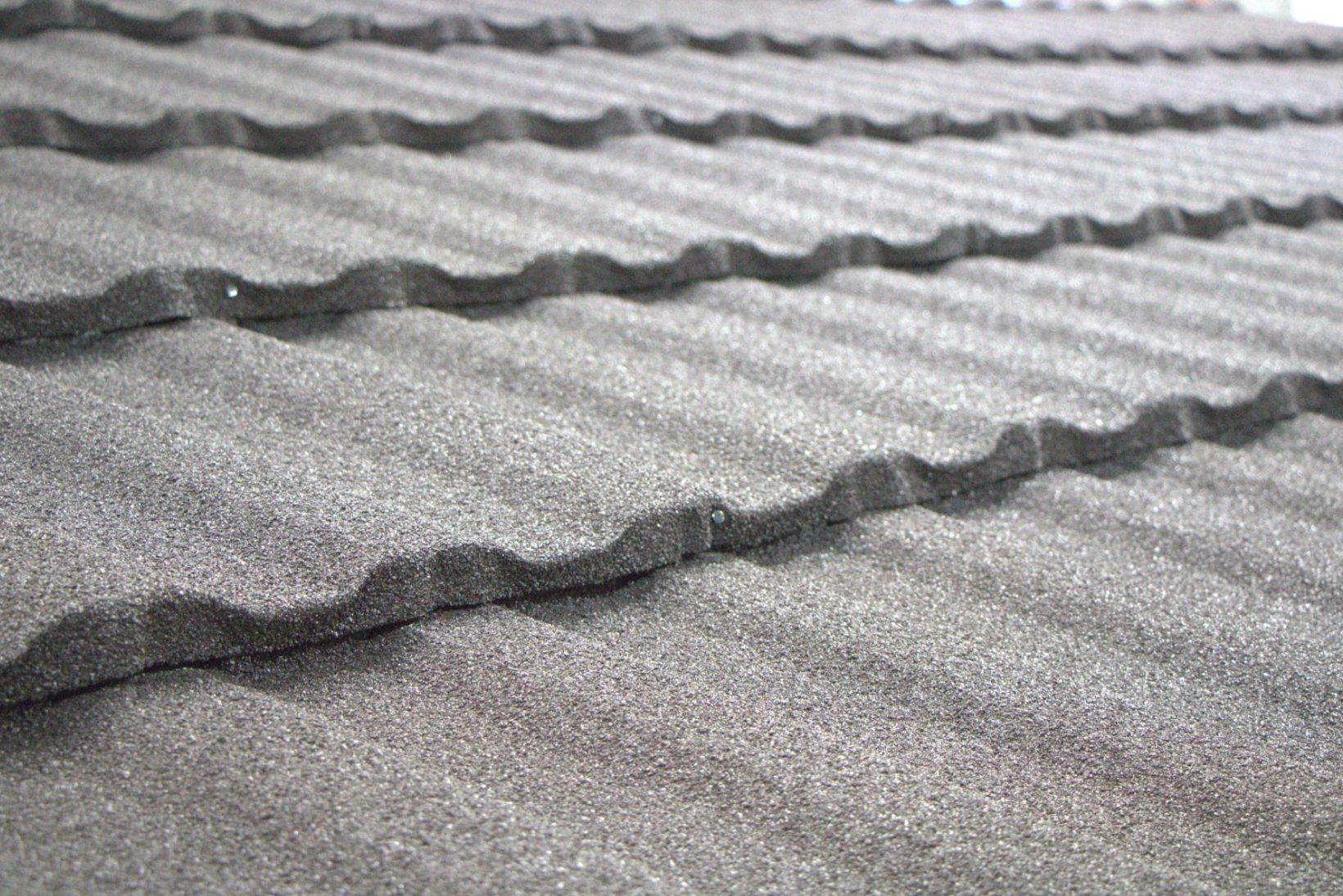

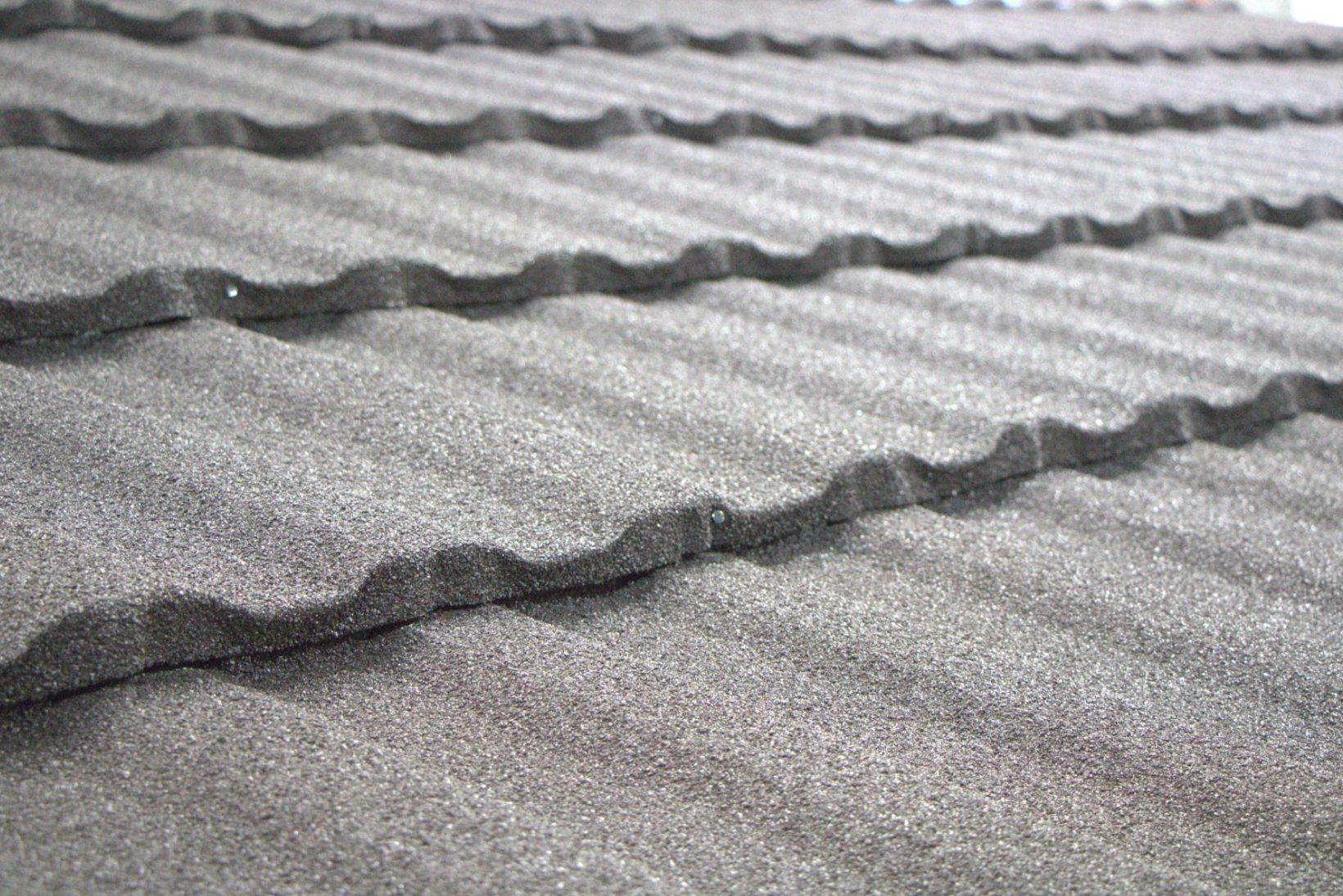

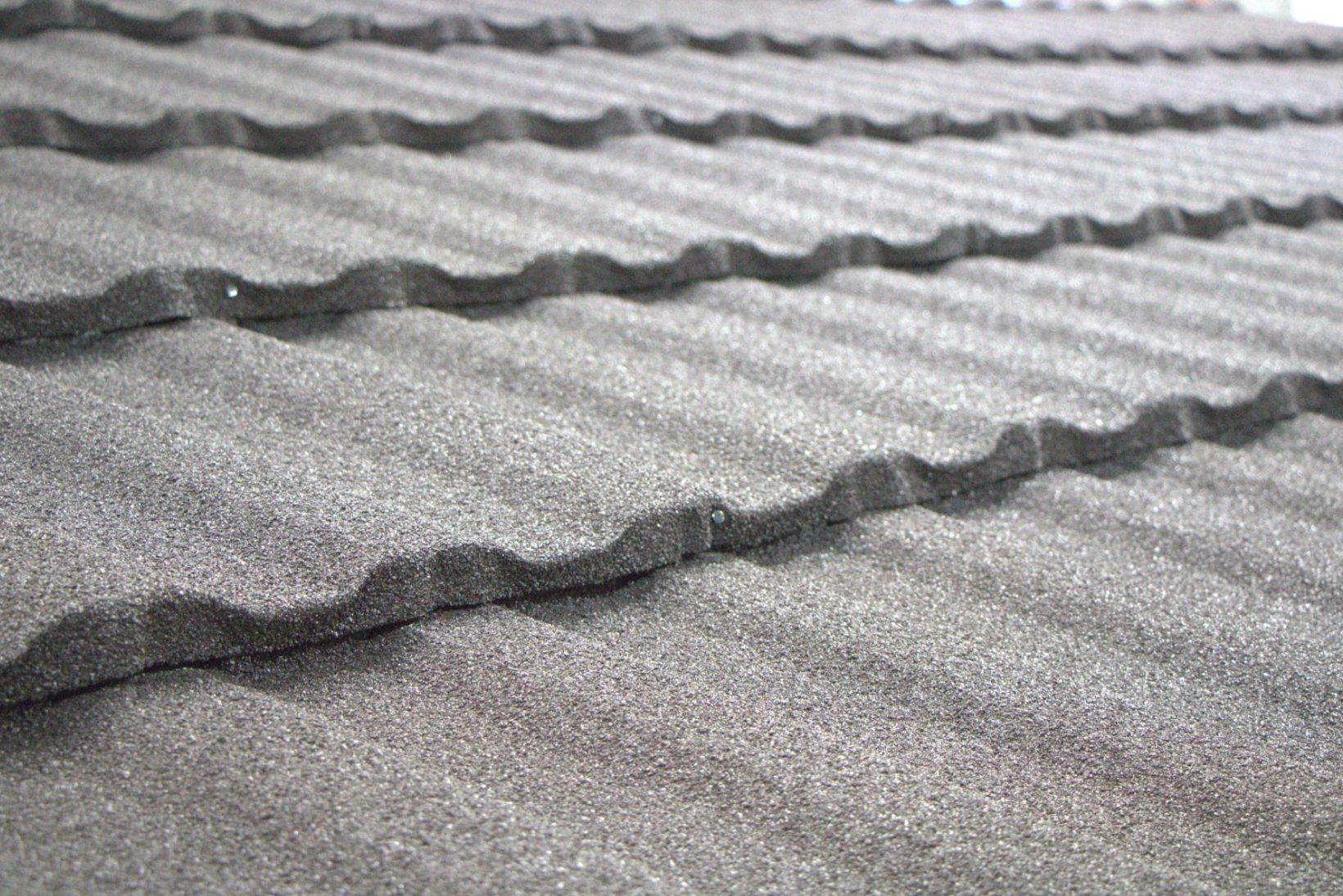

Profile 49

The Britmet Lightweight Roofing lightweight Profile 49 is a classic British profile, now available with all the benefits that only Britmet Lightweight Roofing systems can offer.

Features & Benefits

- Manufactured in Britain

- The only lightweight Redland 49 imitation tile

- Minimum pitch 10 degrees

- 50-year warranty

- AA fire rating equal to traditional roof tiles

- Only weighs 7kg per sqm

Profile 49 Overview

The Britmet Lightweight Roofing’s Profile 49 is a classic British profile with all the benefits that only Britmet Lightweight Roofing systems can offer. This beautiful, contoured tile design offers a great alternative to concrete tiles with its classic traditional aesthetics and Britmet’s revolutionary lightweight properties.

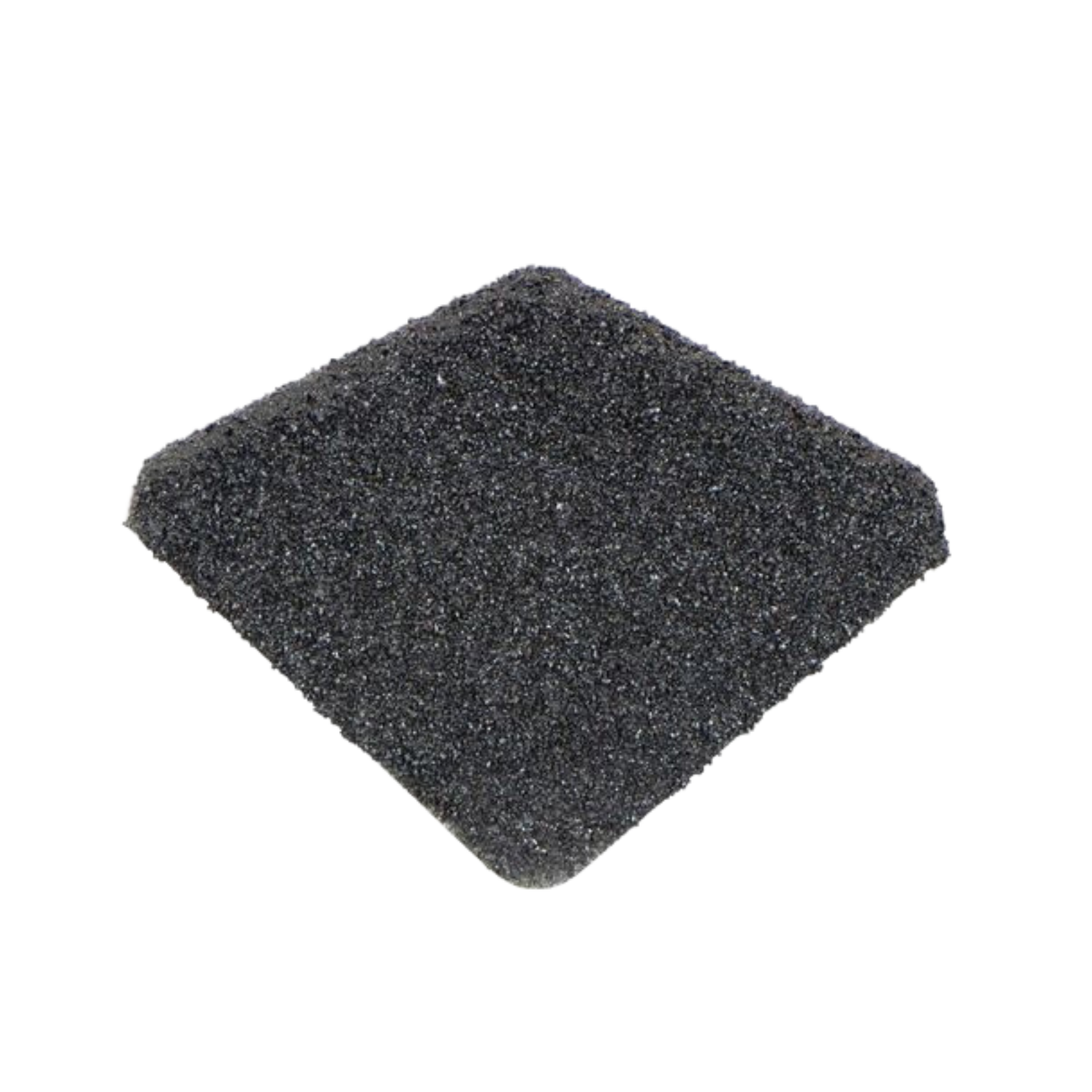

The Profile 49 tile is pressed form high-quality Aluzinc steel, available in a 0.45mm and 0.9mm thickness if an anti-vandal roof is required. Our tiles are coated in a choice of 6 stunning colours while providing superior weather resistance.

Immaculate durability, effortless installation and a wide range of accessories makes Profile 49 one of the most quick and easy roofing solutions from Britmet Lightweight Roofing.

Titanium Grey

Bramble Brown

Rustic Brown

Rustic Terracotta

Moss Green

Currently Unavailable

Tartan Green

Profile 49 Brochure

Profile 49 Photo Gallery

Profile 49 Product Range

Profile 49 Case Studies

Profile 49 Technical Spec

| Minimum pitch: | 10 ° |

| Maximum pitch: | 90° |

| Overall width: | 1420mm |

| Cover width: | 1315mm |

| Side lap: | 105mm |

| Step: | 19mm |

| Batten gauge: | 365mm |

| Batten gauge (0.99mm): | 363mm |

| Roof cover per plate: | 0.48m2 |

| Slates per sqm: | 2.08 |

| Steel base: | 0.45mm & 0.9mm |

| Weight as laid per m2: | 7kg & 11kg |

| Base coat: | Acrylic resin |

| Top coat: | Stone granules with clear acrylic overglaze |

| Chemical resistance: | Non-toxic fungicide incorporated |

| Biological resistance: | Unaffected by normal air pollution |

| Fire resistance: | AA classification equal to traditional roof tiles and slates |

| Fixings: | The contractor shall utilise the roofing manufacturers recommended fixings and sealant |

| Ventilation: | Roof ventilation should meet the recommendations of Building Regulations 1991 (amended ‘92, ‘94). Approved Document F2 1995 ‘Condensation in roofs’, BS 5250: 2021’ Control of condensation’. |

Profile 49 General Specification

Profile 49 panels roof pitches from 10° to 90°

Profile 49 lightweight roofing tiles, to be supplied by Britmet.

Each tile must be secured using 4 coloured 2.6mm x 50mm galvanised fixing nails, driven through the downturned nose of the tile into the face of the battens, (for 0.9mm Profile 49, a coloured Tek screw can be used - part no: ASF2-OOE55)

Note: Stagger bond the tiles

Battens:

Treated tiling battens of approved quality (e.g., tanalised) of suitable section laid at 365mm centres (for 0.45mm thick) or 363mm centres (for 0.9mm thick) except the eaves batten (see eaves section) and secured to the rafters using galvanised nails. Joints in the battens should be staggered and meet halfway across the top of the rafters, as standard code of practice.

Please note: It is the responsibility of the installer to ensure correct batten usage

Underlay:

Approved reinforced felt, BS747 (type 1F) or VPU Breather membrane to be laid over rafters, lapped and secured to the rafters with galvanised clout nails and carried well into gutters. All to comply with current regulations.

Angle hip flashing:

A 38mm x 38mm hip batten should be nailed to the tile battens on each side of the hip rafter, using galvanised nails.

Tiles should be cut and bent to form a 25mm-35mm upstand against the hip battens, using a guillotine and bender (available from Britmet). The hip flashing is to be fitted over the battens and nailed through the downturn, into the face of the battens using five nails on each side.

Eaves:

The bottom course of tiles should be secured using 4 coloured, 50mm Tek screws, driven vertically through the tile. Ideally, the fixing should be near the highest point of the tile profile as possible and driven into the fascia board, or through the eaves batten placed approximately 20mm behind the fascia board if the Profile 49 eaves ventilation system is used. The nail heads to be sealed using the Profile 49 touch up kit.

The top of the fascia board or eaves vent, if used, must be in line with the top of the battens. Then, fit Lay Board or Tilting Fillet at the eaves if appropriate, to ensure any moisture on the underlay drains into gutter.

Eaves Ventilation:

Roof pitch above 15°

The top of the fascia board should be fixed 23mm below the top face of the eaves batten allowing for the Profile 49 10mm eaves vent system.

Roof pitch below 15°

The top of the fascia board should be fixed 25mm below the top face of the eaves batten allowing for the Profile 49, 25mm eaves vent system.

Note: Where the insulation follows the roof slope, the Profile 49 ventilation tray should be installed between the rafters.

Valley:

The valley should be formed from lead, moulded glass fibre or similar approved lining and supported on valley boards. Tile battens should project over the valley to provide fixing for the tiles.

Profile 49 panels should be measured, cut and bent, using the guillotine and bender (available to hire from Britmet) allowing sufficient downturn into the valley.

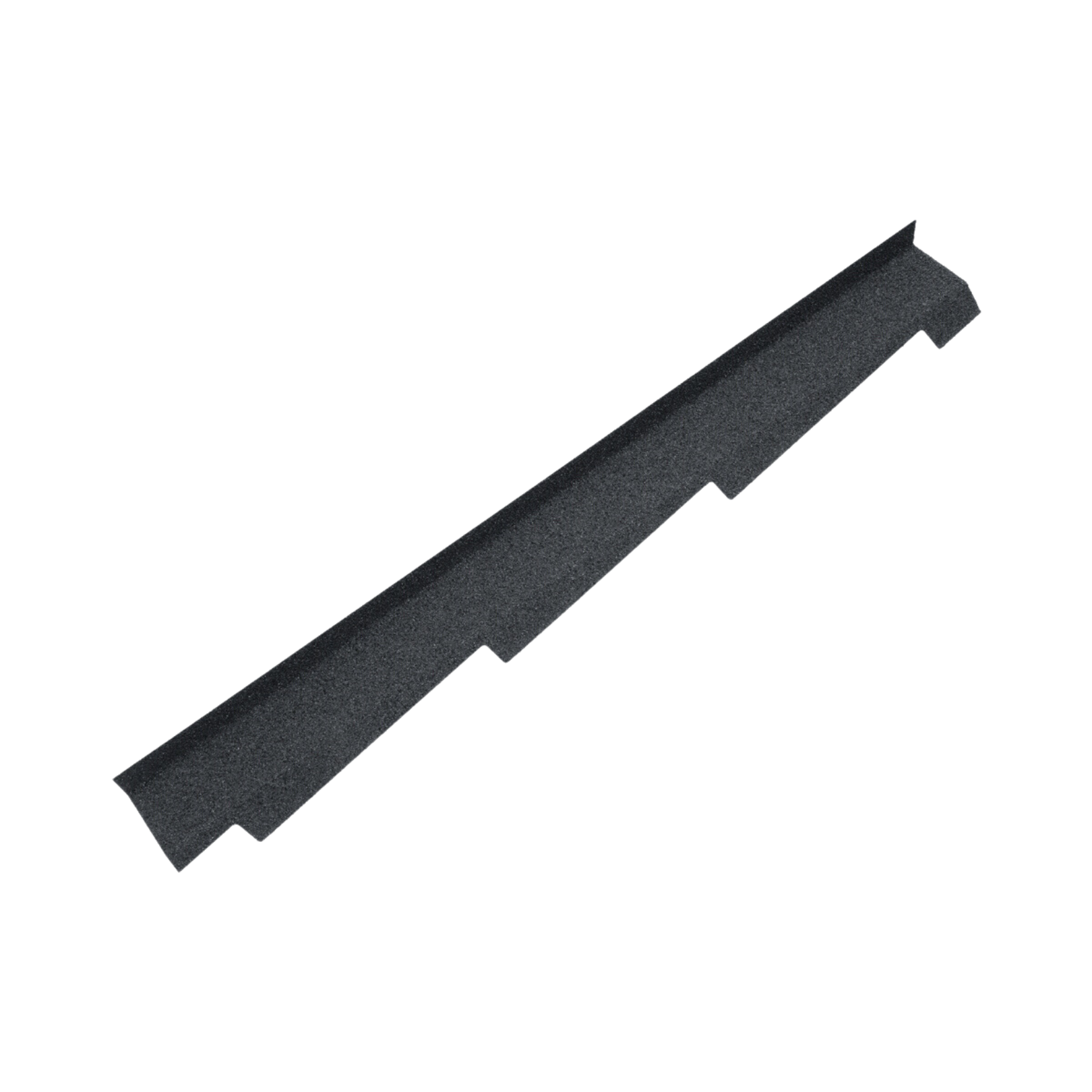

Barge Board Cover:

The timber barge board should project 25mm above the top of the tile battens. A 50mm x 50mm timber batten is to run parallel to the fascia board. Profile 49 panels should be cut and bent up against the timber barge batten.

The Profile 49 scribed barge board cover must be secured using 5 fixing nails driven through the downturned edge and into the barge board. Then five nails are to be driven vertically into the barge batten (the heads of the vertically fixed nails to be sealed, using the Profile 49 touch-up kit.)

Sidewall Flashing:

Profile 49 sidewall flashing is to be secured using fixing nails, one driven vertically into each batten (these nail heads to be covered, using the Profile 49 touch-up kit)

Profile 49 cover flashing should be dressed over the vertical section of the sidewall flashing and be dressed into the brickwork.

Profile 49 Inline Tile and Soil Vent

To provide additional ventilation, the Profile 49 inline tile vents are available providing an airflow of 7,500mm2.

The tile underlay must be cut to allow the spigot of the tile vent to pass through. The Profile 49 panel vent is installed to provide full weather security. The tile vent is secured by overlapping a Profile 49 panel on either side and nailing through the nose of the tile, as previously described. Nails must not penetrate the vent tile.

The Profile 49 inline vent tile can also be used as a weather protected exit point for soil pipes or extractor fan ducts by means of a flexi hose and pipe adapter that connects the vent to 100mm stacks or duct work.

Profile 49 Gas Flue Ridge Terminal

Available to suit angle ridge. Type (R) adapter and extension piece supplied by others.

Please note: This information is to be used as a guide only. It assumes that the structure of the existing building is in accordance with the building practice.

At your request a custom specification can be written for your individual project.

Profile 49 NBS Spec

Profile 49 Installer Guide

Profile 49 Videos

Profile 49 Technical Drawings

| Ref | Description | Files |

| BLR-CAD-PROFILE49-0005 | Profile 49 | DWG | JPG |

| SK-040 | Dimensional Information | DWG | JPG |

| SK-040b | Dimensional Information | DWG | JPG |

| SK-041 | Typical Fixing Detail | DWG | JPG |

| SK-042 | Dimensional Information | DWG | JPG |

| SK-042b | Dimensional Information | DWG | JPG |

| SK-043 | Standard Flashings. Angle Ridge/Hip, Barge Board, Cover and Eaves Apron | DWG | JPG |

| SK-044 | Standard Flashings. Apron, Upstand and Valley | DWG | JPG |

| SK-045 | Typical Ventilated Ridge Detail | DWG | JPG |

| SK-046 | Typical Ventilated Mono Ridge Detail | DWG | JPG |

| SK-047 | Typical Ventilated Eaves Detail | DWG | JPG |

| SK-048 | Typical Barge Detail | DWG | JPG |

| SK-049 | Typical Hip Detail | DWG | JPG |

| SK-050 | Typical GRP Valley Detail | DWG | JPG |

| SK-051 | Sunpipe | DWG | JPG |

| SK-052 | Typical Ventilated Ridge Detail | |

| SK-055 | Profile 49 Tile | |

.png)